Specifically it is an environment friendly and economical storage tank or oil tank installed a floating roof under the vault of the tank usually made of aluminum stainless steel or other material to prevent the.

Landing legs on a floating roof tank.

The roof rises and falls with the liquid level in the tank.

Another option to consider includes reconfiguring the tank bottom to eliminate the presence of a heel after the discharge pump loses suction.

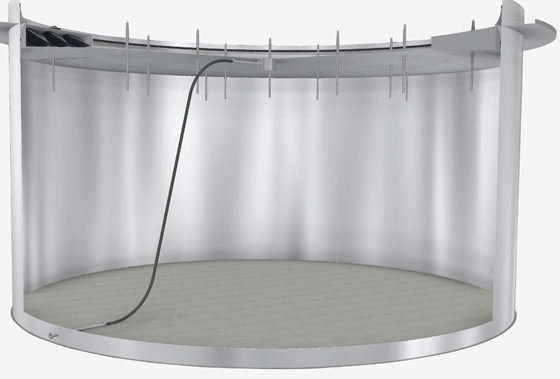

It consists of an open topped cylindrical steel shell equipped with a roof that floats on the surface of the stored liquid.

Internal floating roof tank is known as internal floating roof storage tank floating roof oil tank internal floating plate storage tank and internal floating plate oil tank etc.

Failures of floating roof primary and secondary seals foam filled or liquid filled have been a significant concern.

The leg sock provide the following features.

The leg sock are designed to prevent product loss caused by vapors escaping from floating roof support legs.

The length of the legs must be adjustable from the top of the roof and the legs must be notched or perforated at the bottom to provide drainage.

Compatible for 100 aromatics.

The floating roof must be provided with landing legs that are designed to support the external floating roof under a uniform design load of at least 25 psf api 650 appendix c 3 10.

Poor tank turnaround practices with inadequate checking of roof supports.

A design requirements 1 rim seals.

When emptying floating roof tanks landing the legs will create a vapor space above the liquid thus causing air to be drawn in through the roof seals.

An ifr shall be equipped with one of the seal configurations listed in paragraphs a 1 i a through a 1 i c of this section.

There was a fatality on a large diameter floating roof tank when a contractor died under the weight of the roof plates which collapsed on him.

The picture above shows an external floating roof with the roof legs in the high position in this position there is typically about 6 of space between the floor and roof.

Can be used with either u type or t bar leg handles.

Floating roof landing losses21 when using floating roof tanks the roof floats on the surface of the liquid inside the tank and reduces evaporative losses during normal operation.

The roof leg is pinned through the sleeve in this position prior to landing the roof to do maintenance inside the tank.

This decreases the size of the vapor space and corresponding losses.

Can be installed while tank is in service.

The resulting atmosphere may be in the flammable range.

Landing a floating roof on low legs is an excellent and easy way to lower emissions during rvp landings.

Seams are factory welded.

The owner or operator who elects to use a floating roof to comply with the requirements of 63 1062 shall comply with the requirements in paragraphs a through e of this section.

An external floating roof tank is a storage tank commonly used to store large quantities of petroleum products such as crude oil or condensate.